FIT FOR SERVICE ASSESMENTS

We can determine the structural integrity of your steel storage & piping equipment. Through visual & detailed equipment inspections, ultrasonic thickness & metal loss measurements, we can accurately determine the condition of your equipment and recommend engineering solutions & operational controls to mitigate any operational losses or safety related incidents.

Our Fitness for Service Assessment services will includes the following:

- Visual inspections, Level 2 & Level 3 inspections

- FFS calculations & recommendations based on API 579-1/ AMSE FFS-1; API 580; & API 653 (repairs)

- ASME B31/ B31G, determining remaining strength of corroded pipelines.

- Ultrasonic thickness inspections & metal loss assessments

- Failure Mode and Effect Analysis: Determining the causes of failures & resultant effects, mitigation strategies & post mitigation results.

Typical storage vessel failures include the following:

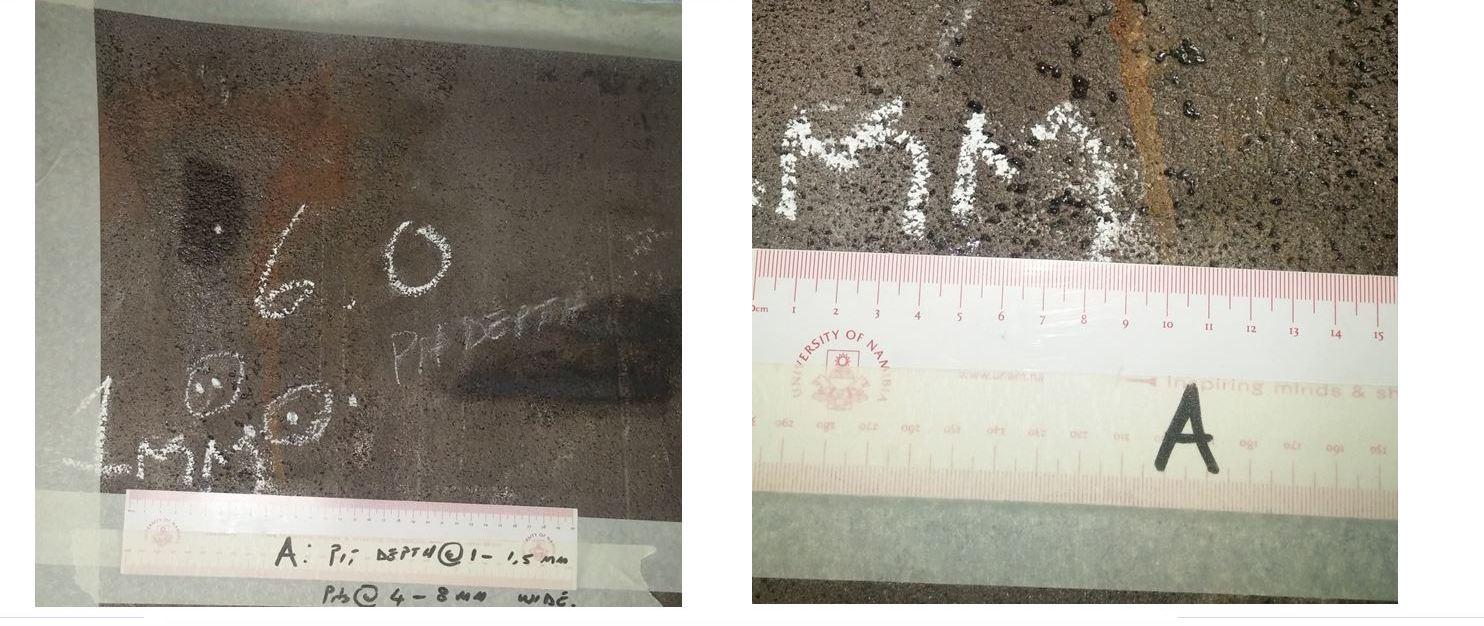

- Pitting corrosion & general metal loss

- Out of roundness

- Flat zones in tank shell

- Dents & gouges